mRegz™ AirCompliance

Enhance compliance & process safety with reduced emissions for process industries

Enhance your daily operations with continuous emissions monitoring

Step into the forefront of fugitive emission leak detection evolution with mRegz™ AirCompliance. Our state-of-the-art solution provides continuous monitoring, accurately locating emission leaks in process industries, with precision ranging from low to high parts-per-billion detection. Establish environmental stewardship, elevate safety standards, ensure regulatory compliance, and optimize operational workflows with our cutting-edge AIoT-enabled emissions monitoring solution. Uncover the transformative power of continuous leak detection intelligence, gaining a strategic advantage while effectively minimizing fugitive emissions.

Improve oversight of industrial operations, reduce fugitive emissions, and enhance community safety while maintaining adherence to governance standards

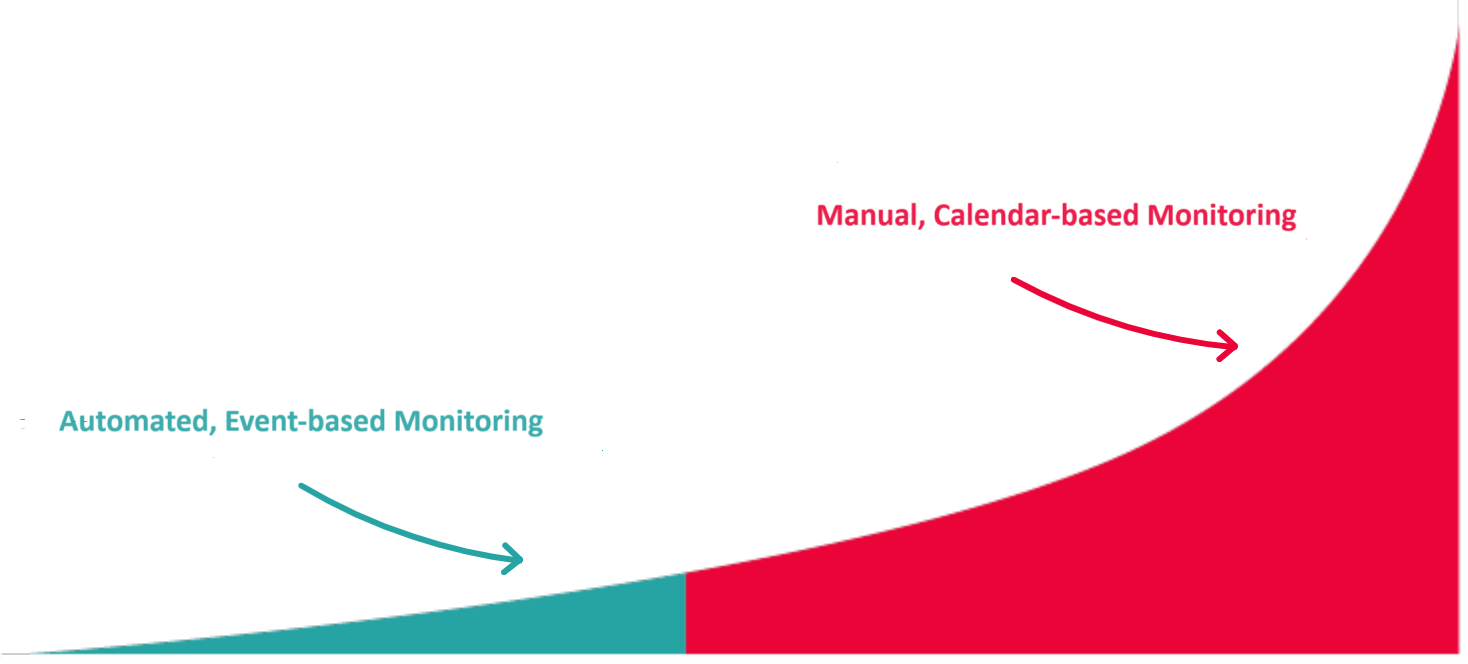

REDUCED CUMULATIVE DAILY EMISSIONS WITH EVENT-BASED MONITORING

-AirCompliance.png?width=692&height=564&name=mobile-graph%20(1)-AirCompliance.png)

Case Study

mRegz™ AirCompliance Solution

mPACT2WO’s AirCompliance solution helped a large U.S. refinery with early detection of emissions at a high pressure hydrocarbon processing unit to avoid a costly shutdown.

Customer Success Stories

- Asset: Remote pump station site (pipelines & terminals)

- Problem: Unidentified emissions at a remote site impact production and environmental safety, potentially escalating cleanup costs and repairs.

- Solution: mRegz™ AirCompliance solution sent an alert showing a category 2 emission peak at 46 ppm.

- Benefit: Early detection minimizes gasoline loss to a few gallons; leak fully resolved in 7 hours.

- Asset: High-pressure hydrocarbon processing unit

- Problem: Emissions go undetected until the scheduled quarterly monitoring, with increased risk exposure.

- Solution: mRegz™ AirCompliance alerted ops about a Category 1 leak (> 3000 ppbe) in the high-pressure section, identified in 30 minutes.

- Benefit: Early detection and location info allowed a controlled shutdown, swift leak repair, and a safe restart the next day.

- Asset: Hydrogen compressor

- Problem: Undetected emissions on equipment not in routine AVO or LDAR monitoring pose an increased safety risk.

- Solution: LDSN detected a Category 1 high emission within hours, notifying the Operations and LDAR team of a leaked recycled hydrogen.

- Benefit: Decisions were made to take equipment offline for repairs.

- Asset: Tank farm conservation vent

- Problem: Abnormal emissions at an authorized source pose a potential risk.

- Solution: mRegz™ AirCompliance alerted ops; personnel dispatched within minutes.

- Benefit: Within 4 hours of notification, the emission source was located and corrected, staying within limits.