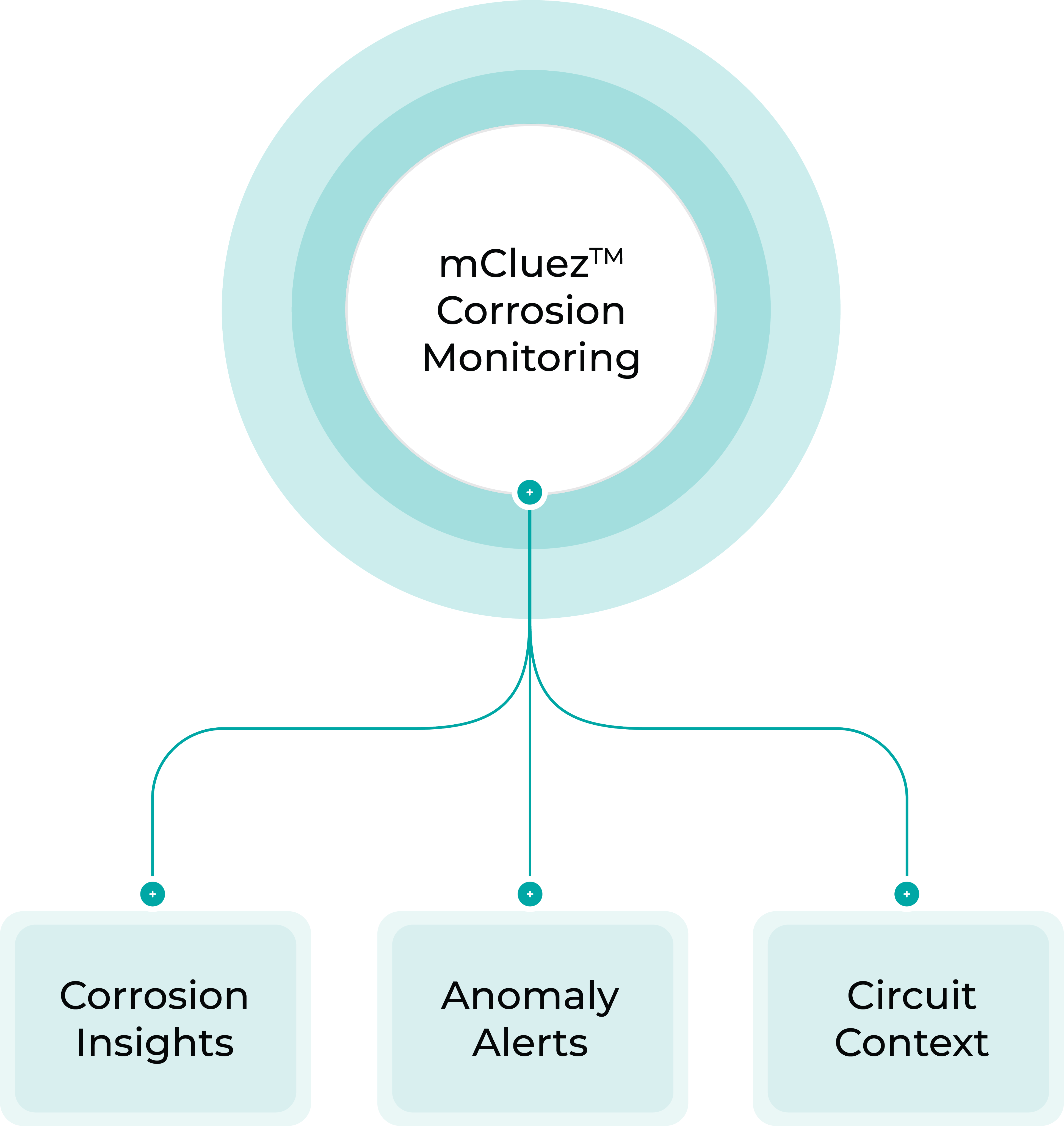

mCluez™ Corrosion Monitoring

Achieve operational excellence, safeguard assets, and minimize risks in process industries

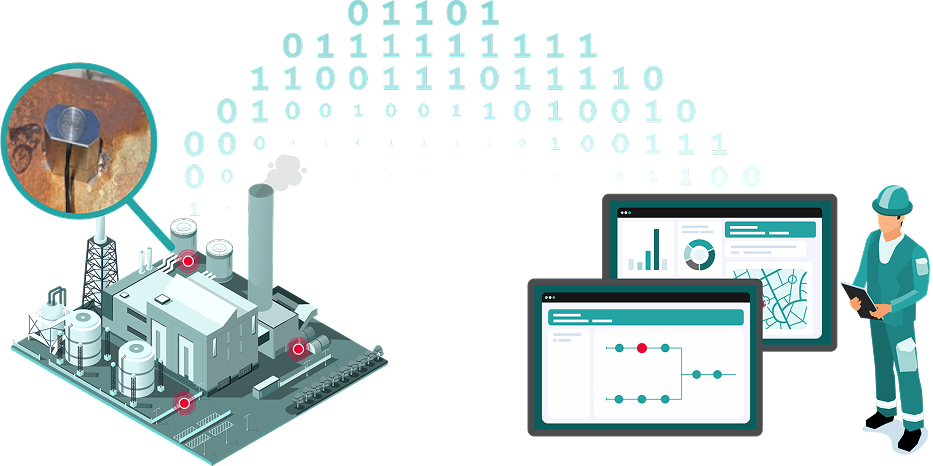

Corrosion creates serious safety, operational, and financial risks in process industries. mCluez™ Corrosion Monitoring uses advanced ultrasonic sensors and AIoT analytics for early corrosion detection, helping prevent failures and minimize downtime. Designed for process industries such as oil and gas, refineries, and chemical plnats, mCluez™ enables engineers and inspectors to maintain safety, efficiency, and operational predictability.

Powered by AIoT (Artificial Intelligence of Things) and NDE4.0 (Non-Destructive Evaluation 4.0), mCluez™ delivers precise thickness measurements and continuous monitoring of critical locations, providing actionable insights for strategic maintenance and long-term reliability.

Discover Real-World Success

Learn how mCluez™ Corrosion Monitoring transforms industrial operations with precision, efficiency, and actionable insights. From enhancing equipment safety and extending asset lifespan to preventing costly downtime, our innovative solutions deliver measurable value across industries.

With advanced early detection capabilities, mCluez™ empowers operators to address corrosion threats before they escalate, ensuring continuity and optimal performance.

-

Alkylation Process Unit

Challenge

Manual inspections uncovered high corrosion, jeopardizing equipment life and performance.

Solution

mCluez™ highlighted high corrosion rates, aiding troubleshooting and offering insights into equipment life and safety.

Outcome

Early identification of high corrosion rates informed timely plant decisions, assessing their impact on equipment life.

-

Deisohexanizer (DIH) Process Unit

Challenge

Manual thickness readings take years to detect high corrosion, making it inefficient.

Solution

mCluez™ detected a spike in corrosion rates, linked to inactive inhibitor pump timelines.

Outcome

Early detection provided timely insights, preventing downtime and safeguarding assets.

-

Degassing System

Challenge

Elevated temperatures and process changes caused high corrosion in a critical degassing system.

Solution

With mCluez™ insights, the Operations and Maintenance team lowered temperatures and adjusted processes, reducing corrosion rates.

Outcome

Early detection allowed timely operational decisions, mitigating corrosion impact on equipment life.

Why Choose mCluez™ Corrosion Monitoring?

Imagine the impact of an unexpected rate of corrosion leading to a critical asset failure—risking safety, halting operations, and incurring costly repairs. These challenges are a reality in process industries every day. mCluez™ transforms corrosion management with:

Real-Time Insights

Continuously monitor corrosion rates and material integrity with advanced sensors and analytics.

Early Warnings

Detect corrosion issues before they escalate, reducing unplanned downtime and repair costs.

Risk Mitigation

Make timely, data-driven decisions to enhance safety and operational efficiency.

Stay ahead of corrosion risks with mCluez™, ensuring seamless operations and asset integrity in even the most demanding industrial environments.

From the Ground Up—Innovating Corrosion Management

mCluez™ empowers essential roles across industries, ensuring effectiveness and operational excellence in corrosion monitoring and prevention.

Who Benefits from mCluez™?

Service Supervisors

Operations

Corrosion Engineers

Maintenance Inspectors

Reliability Engineers

Corporate Safety Leaders

-

Service Supervisors

- Streamlined Inspections: Access live data and comprehensive reports to optimize inspection schedules.

- Enhanced Coverage: Ensure thorough and effective corrosion monitoring across all assets.

-

Operations

- Continuous Asset Oversight: View dashboards and insights on corrosion rates and critical asset life in process units.

- Early Anomaly Detection: Spot and address issues early to minimize repairs, enhance safety, and keep operations running smoothly.

-

Corrosion Engineers

- Advanced Analytics: Leverage historical data and analytics to develop robust prevention strategies

- Vital Asset Protection: Extend asset longevity while safeguarding operational safety.

-

Maintenance Inspectors

- Early Detection: Receive timely alerts to swiftly identify and address potential corrosion issues.

- Operational Continuity: Protect equipment integrity with proactive maintenance insights.

-

Reliability Engineers

-

Proactive Solutions: Use early detection data to mitigate risks and minimize operational disruptions.

-

Critical Infrastructure Support: Keep core systems running with minimal interruptions.

-

-

Corporate Safety Leaders

-

Regulatory Alignment: Implement technologies that meet stringent safety regulations and standards.

-

Risk Mitigation: Reinforce a safety-first approach to protect assets and ensure compliance.

-

-

Plant Operators

- Simplified Oversight: Intuitive dashboards offer a clear view of corrosion status, making asset management straightforward. Instant alerts enable quick responses to critical changes.

- Operational Gains: Consistent monitoring helps reduce downtime, reinforce safety, and improve overall plant performance.

With mCluez™, you're not just managing corrosion— you're setting a new standard for operational excellence.

Precision Meets Simplicity in Corrosion Monitoring

Elevate your asset management with mCluez™, delivering precise corrosion monitoring powered by cutting-edge ultrasonic sensors and advanced analytics. Experience seamless operations with automated precision, providing actionable insights to optimize processes, maximize operational efficiency and enhance asset reliability. Embrace the user-friendly design of a consumer app, intuitively crafted for corrosion engineers and inspectors, requiring no training for immediate adoption and impact.

Achieving Operational Excellence with mCluez™

Key Benefits

ONE Solution, Multiple Applications

- Simplify complexity and enhance effectiveness across assets like HF Alky Units, Crude Units, Sulphur Recovery Units, Wellhead piping, Midstream Terminals, and Flare Systems.

Real-Time Anomaly Detection

- Automated insights replace scheduled inspections for quick responses, minimizing downtime and ensuring seamless operations.

Advanced Detection Technology

- High-fidelity ultrasonic sensors ensure comprehensive coverage and early issue identification.

- Accurate thickness measurements with temperature correction and dynamic material velocity.

- Event-driven insights offer extensive system-wide coverage.

Visual Analysis and Alerts

- Simplified root cause analysis through circuit views.

- Optimize processes and maintenance with detailed unit views.

Scalable Growth

- Seamlessly adapt and expand to meet evolving operational demands.

- Streamline your workflow with our easy-to-use cloud solution, offering automatic updates, 24/7 support, and quarterly reports.

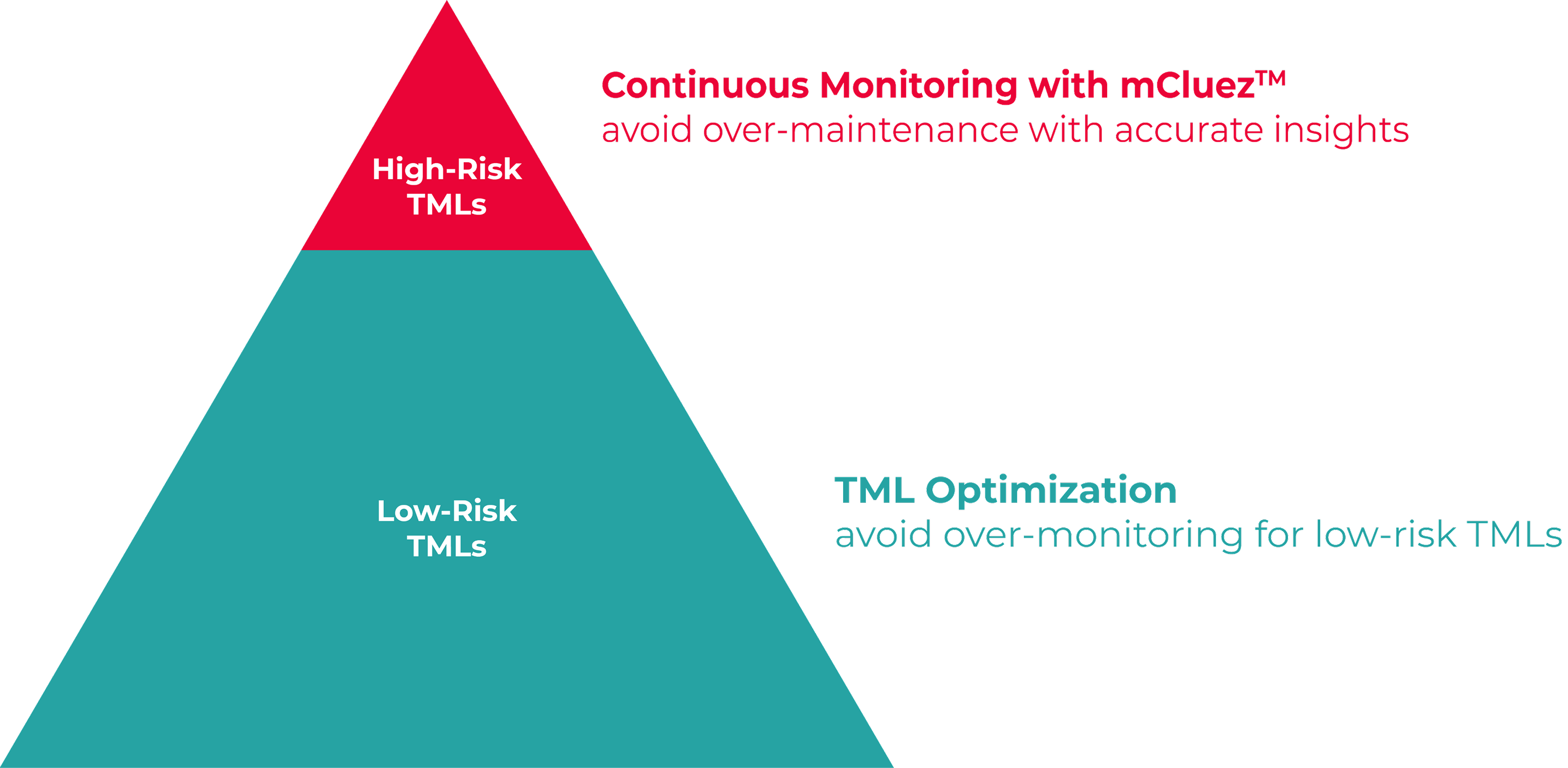

Smarter Corrosion Management with mCluez™

mCluez™ Corrosion Monitoring delivers precision and reliability, enabling industries like oil and gas, petrochemical, and chemical manufacturing to address corrosion risks and optimize operations. Using advanced ultrasonic sensors and analytics, mCluez™ detects corrosion early with precise measurements and temperature correction, ensuring asset integrity. Automated alerts notify teams of anomalies for swift, safety-focused action. Circuit-level insights help operators quickly pinpoint problem areas for targeted maintenance, streamlining workflows and minimizing downtime. mCluez™ is essential for enhancing safety, efficiency, and reliability in today’s industrial environments.