Papers & Case Studies

- ALL

- Papers

- Case Studies

Case Study

Corrosion

Early Corrosion Detection for the EDC Reactor Cooler

Leveraging mCluez™ for Enhanced Asset Reliability Through Proactive Corrosion Monitoring

Case Study

AirCompliance

Early Detection to Reduce Emissions in Pump Station Deadlegs of Pipeline and Terminal Operations

Reducing Environmental Risks, Lowering Cleanup Costs, and Mitigating Product Loss

Case Study

Corrosion

Early Corrosion Detection in Alkylation Depropanizer

Accurate Corrosion Insights Extend Equipment Life and Defer Costly Replacements

Case Study

AirCompliance

Early Detection of LPG Leaks in Heat Exchangers

Timely Insights for Quick Response and Enhanced Personnel Safety

Case Study

Corrosion

Early Corrosion Detection for Degassing System

Unlocking Insights into Corrosion to Reveal Elevated Rates and Lineup Correlations

Case Study

AirCompliance

Early Leak Detection for Fenceline Emissions

Mitigates Risk, Maintains Compliance within Threshold

Case Study

AirCompliance

Timely Emissions Mitigation for Remote Site

Minimizes Production Loss and Reduces Environmental Hazards

Case Study

AirCompliance

Category 1 Emissions at Toluene Fractionation

Early Emission Detection Enables Quick Response

Case Study

AirCompliance

High-Pressure Leak

Early Emission Detection Enables

Quick Response

Case Study

AirCompliance

Preventing Abnormal Emission Condition

Maintaining a Safer Work Environment via Faster Leak Response Times

Case Study

Corrosion

Corrosion Monitoring for Alkylation Process Unit

Timely Insights to High Corrosion Rates and Performance During Early Phases of Life Cycle

Case Study

Corrosion

Corrosion Monitoring for Process Unit

Timely Insights of Process Impact on Fixed Asset Health

Paper

AIoT-Driven Deadleg Corrosion Monitoring: Future-Ready Asset Integrity Management

Permanently installed ultrasonic sensors, combined with AIoT and NDE 4.0, provide an excellent solution for material evaluation.

Source: Pipeline Technology Journal

Paper

Fenceline Monitoring Now Required for Toxic Air Pollution Rules

Advanced early detection enabled by Artificial Intelligence of Things (AIoT) enhances emissions monitoring by ensuring real-time data accuracy and quick issue resolution, improving environmental compliance and operational efficiency.

Source: plantengineering.com

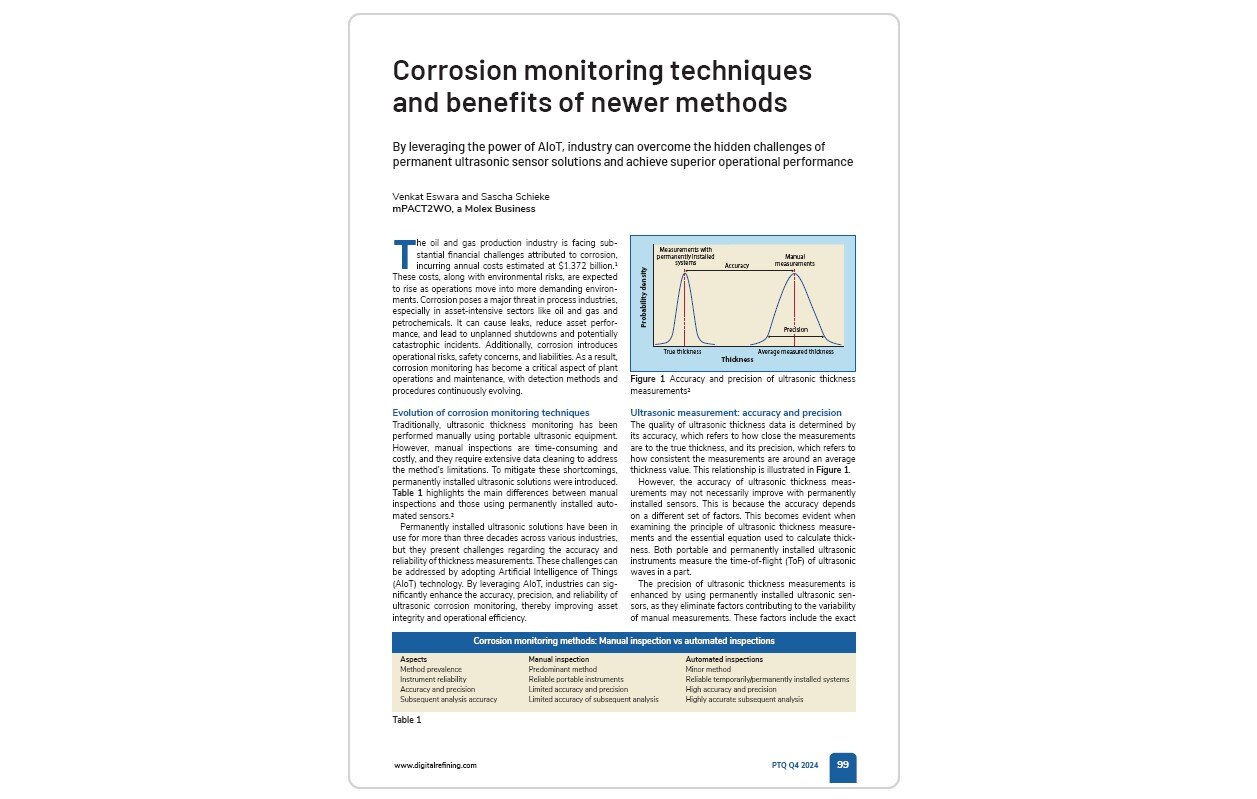

Paper

Corrosion Monitoring Techniques and Benefits of Newer Methods

By leveraging the power of AIoT, industry can overcome the hidden challenges of permanent ultrasonic sensor solutions and achieve superior operational performance

Source: ptqmagazines.digitalrefining.com

Paper

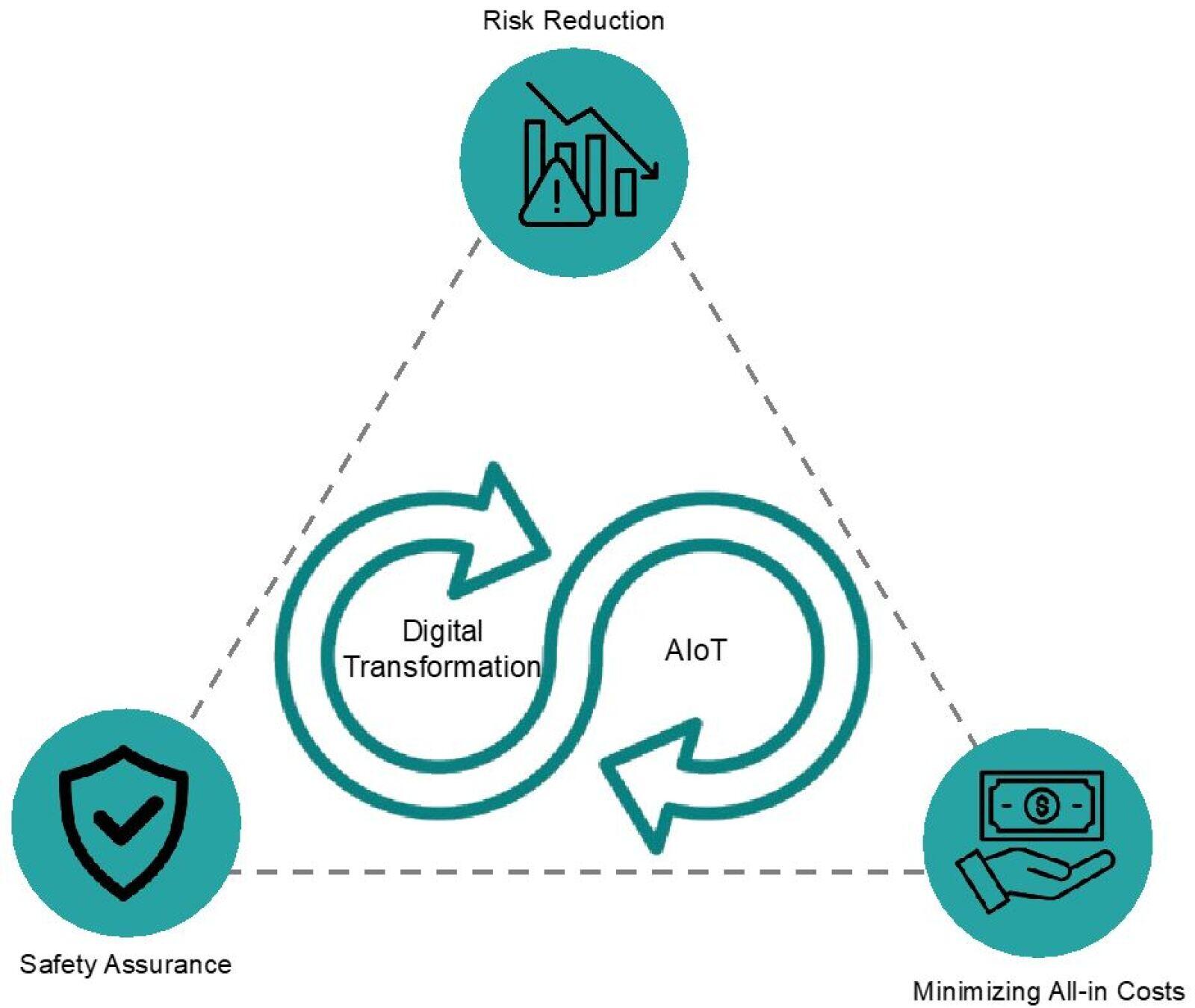

Top Three Objectives for Digital Transformation in Emissions Monitoring

Explore how integrating these three objectives—risk reduction, safety assurance, and minimizing all-in-costs—into digital transformation strategies enables operators to effectively manage emissions and achieve success.

Source: jpt.spe.org

Paper

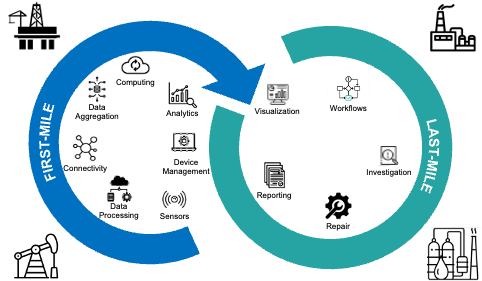

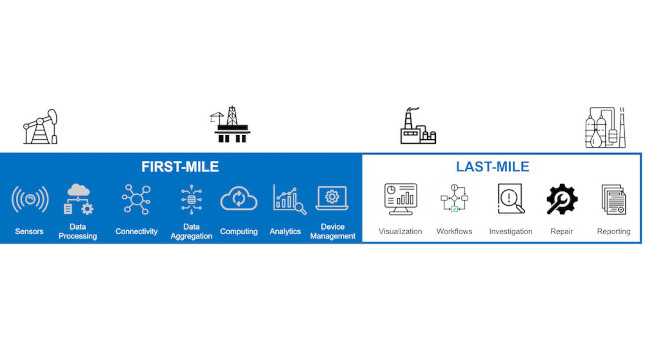

Unleashing AIoT for Industrial Operators with a Right-to-Left Approach

AIoT holds the potential to disrupt and transform the industrial segment including the oil and gas sector, leveraging a distinctive right-to-left approach.

Source: oilmanmagazine.com

Paper

AI Operator-centric Next-gen Corrosion Monitoring

Refineries, chemicals, and other industrial facilities can benefit significantly from the use of new AI-driven solutions utilizing more sophisticated ultrasonic sensors for corrosion monitoring.

Source: arcweb.com

Paper

Effective corrosion monitoring

Explore how effective corrosion monitoring at scale can prevent catastrophic events and ensure the safety of critical assets in the downstream industry.

Source: hydrocarbonengineering.com

Paper

The Benefits of Artificial Intelligence of Things (AIoT) in Modern Oil and Gas Leak Detection

A pivotal component in obtaining reliable and actionable data for emissions reduction is the implementation of a continuous emissions monitoring solution spanning from the ‘first mile’ to the ‘last mile.’

Source: iiot-world.com

Paper

How to Proactively Reduce Leaks and Emissions in Oil and Gas

Plant managers and engineers in process-focused industries are seeking ways to reduce fugitive emissions to provide a safer work environment and reduce their facilities’ environmental footprint

Source: plantengineering.com

Paper

Growth, Community & Future-Proofing

The team at Flint Hill Resources explains how keeping up with demand and community engagement is enhancing its services.

Source: tankstorage.com

Paper

Flint Hills Resources’ Dillon: Safety, Stewardship Remains a Priority

The novel LDAR system enhances detection of abnormal conditions that could lead to occupational or process safety events, creating a safer work environment and improving data quality.

Source: bicmagazine.com

Paper

Refineries Can Reduce Leak Repairs by Monitoring Emissions

Cutting oil refinery leak repair times by 80 percent through game-changing fixed, continuous emissions monitoring

Source: digitalrefining.com

Paper

AI-Driven Leak Detection Best Practice Trends

Industrial organizations can gain advantage by pursuing operator-centric solutions for minimizing fugitive emissions and leaks

Source: arcweb.com

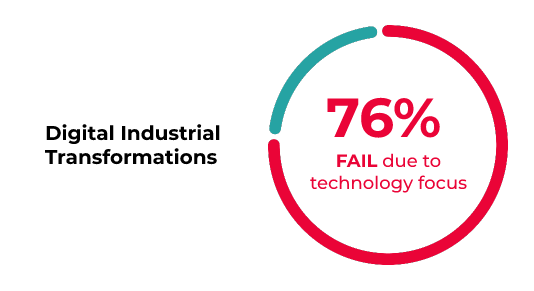

Paper

The Road to Digital Industrial Operators

An operator-first approach to digital technology adoption and transformation is a more effective path to a higher value workforce