mRegz™ AirCompliance

Ensure operational reliability, enhance safety, and reduce emissions

Operational reliability and environmental safety are essential in today's process industries. mRegz™ AirCompliance leverages advanced AIoT technology for precise, continuous detection of fugitive emisssions—down to parts-per-billion—while its inuitive app empowers your workforce and helps protect operations.

Designed for process industries—including oil and gas, petrochemical, and chemical sectors—mRegz™ AirCompliance supports efficient operations and empowers teams with real-time monitoring and actionable insights. The result is safer, more predictable operations, a reduced environmental footprint, and a solution that grows with your needs.

Discover Real-World Success

Learn how our innovative solutions drive precision, efficiency, and impact across industries. From enhancing safety and compliance at process units, fencelines, and remote sites to swiftly resolving critical challenges, our success stories showcase our unwavering commitment to operational excellence and environmental sustainability.

Explore how we’re transforming industry challenges into meaningful results—one success story at a time.

-

Remote Pump Station Site

Challenge

Undetected emissions were impacting safety and production.

Solution

Achieved early detection of a Category 2 emission at 46 ppm.

Outcome

Minimized gasoline loss and resolved the issue within 7 hours, significantly enhancing safety and operational efficiency.

-

High-Pressure Hydrocarbon Processing Unit

Challenge

Emissions went unnoticed during scheduled monitoring, increasing risk exposure.

Solution

Detected a Category 1 leak (> 3000 ppbe) within 30 minutes.

Outcome

Enabled a controlled shutdown, swift leak repair, and safe restart, reducing operational risks.

-

Barge Loading Dock

Challenge

Faced the risk of losing regulatory approval due to benzene exceedances.

Solution

Issued an alert pinpointing the source and time of emission within 24 hours.

Outcome

Enabled swift remediation efforts and secured a permit from the regulatory agency for proactive compliance and response, significantly enhancing environmental protection.

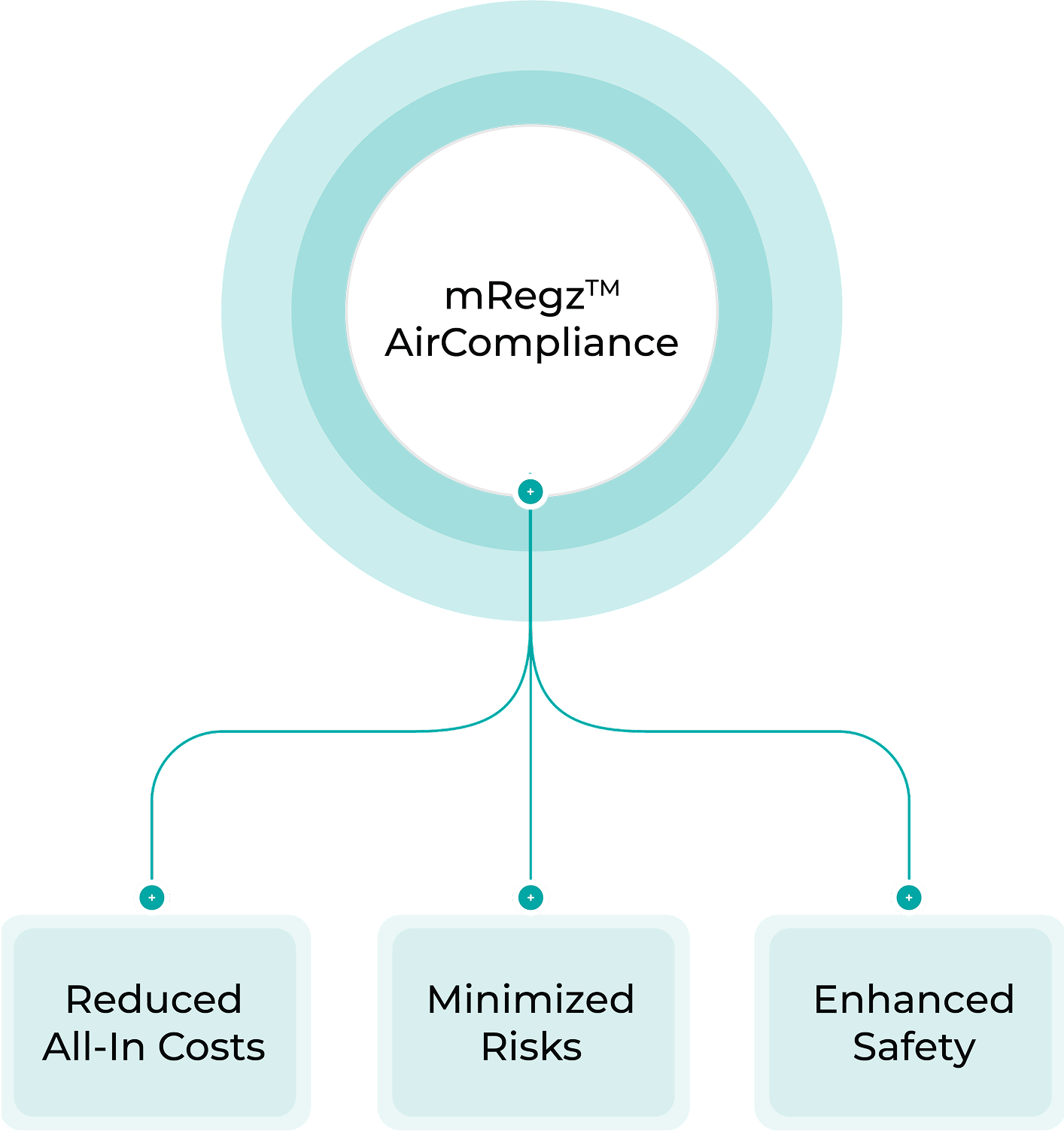

Why Choose mRegz™ AirCompliance?

Imagine the impact of an unnoticed emission triggering an emergency shutdown—

halting production and driving up costs. For many process industries, this risk is all too real.

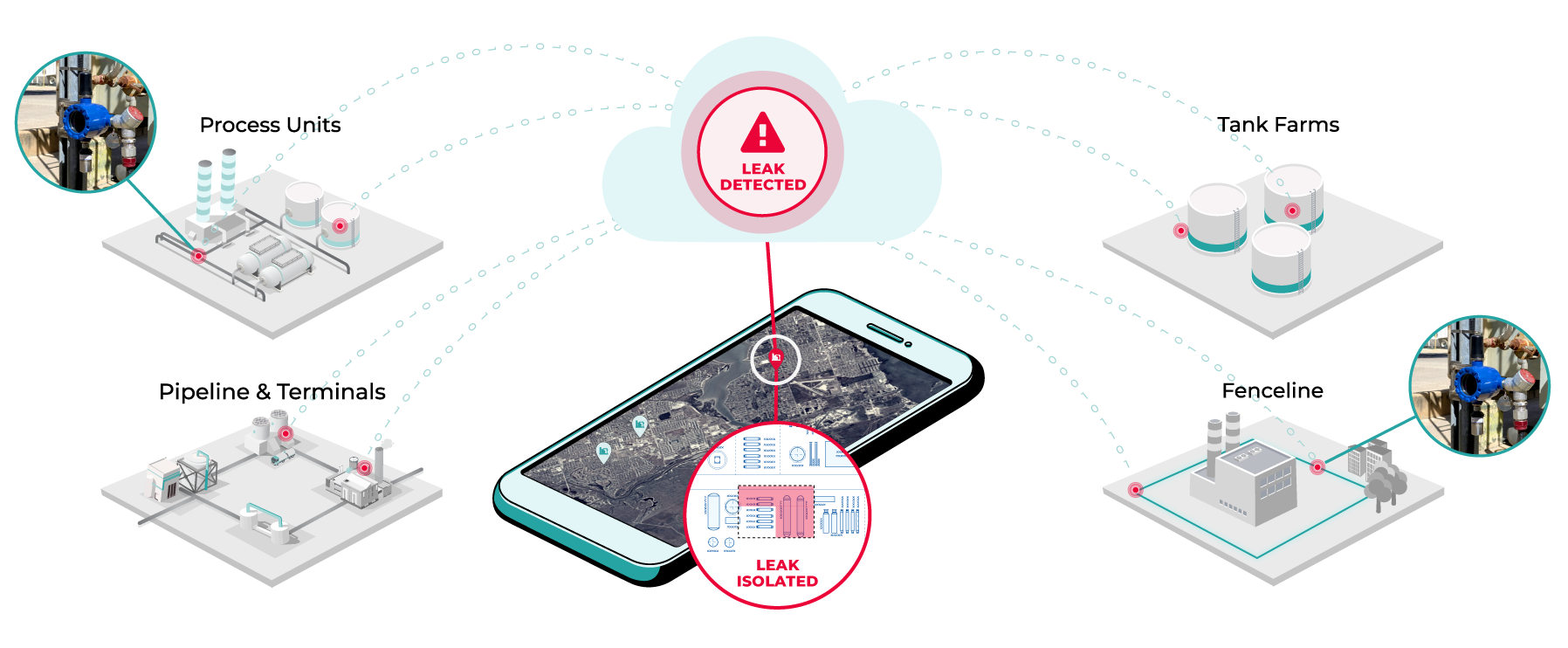

24/7 Monitoring

Advanced sensors accurately detect leaks the moment they occur.

Real-Time Alerts

Notify your team instantly to address risks before they escalate.

Proactive Prevention

Maintain compliance, enhance safety, and streamline operations effortlessly.

Stay ahead of risks—mRegz™ AirCompliance ensures you’re always in control.

Empowering Operational Excellence and Compliance Across Industries

mRegz™ AirCompliance enables boots-on-the-ground teams and decision-makers to excel in emissions management, compliance, and environmental stewardship.

Who Benefits from AirCompliance?

Supervisors

Operations

LDAR Technicians

EHS

Corporate

-

Supervisors

- Actionable Insights: Leverage real-time data for better environmental practices.

- Regulatory Confidence: Meet compliance standards with accurate monitoring.

-

Operations

- Automated Emissions Oversight: Easily track, record, and resolve emissions with intelligent automation for efficient, compliant operations.

- Instant Anomaly Notifications: Get real-time alerts on high-emission events for fast response and corrective action.

-

LDAR Technicians

- Precision Tools: Quickly locate and repair leaks with pinpoint accuracy.

- Safety Assurance: Keep operations aligned with environmental goals.

-

EHS (Environmental Health & Safety) Supervisors

- Visual Dashboards: Intuitive displays offer clarity and actionable information.

- Efficient Compliance: Achieve regulatory standards with ease.

-

Corporate Sustainability Officers

- Scalable Solutions: Enterprise-ready tools help you meet sustainability goals.

- Environmental Leadership: Demonstrate your commitment to a cleaner future.

-

Plant Operators

- Efficient Solution: Intuitive features within the system help plant operators streamline and manage emissions effectively from the control room.

- Real-Time Alerts: Receive instant notifications to quickly address and resolve issues as they arise in plant operations.

Go Beyond Compliance to Operational Excellence

With mRegz™ AirCompliance, you’re not just monitoring emissions—you’re advancing safety, compliance, and environmental progress at every level of your organization.

Experience State-of-the-Art Emissions Monitoring

Elevate safety, streamline workflows, and stay ahead of compliance challenges with technology built to proactively manage risks.

Transform your emissions management with mRegz™ AirCompliance—a powerful solution combining high-fidelity sensors, advanced analytics, and optimized workflows. Paired with a user-friendly, app-like interface, it ensures effortless adoption and trusted insights for enhanced operational efficiency.

- Intuitive Interface: Consumer-grade design enables quick and easy adoption without extensive training.

- Advanced Detection: Pinpoint VOCs (Volatile Organic Compounds), HAPs (Hazardous Air Pollutants) like benzene, and other emissions at the earliest stage.

- Timely Notifications: Empower your team to act swiftly on anomalies before they escalate.

Elevate Your Operations with Precision and Flexibility

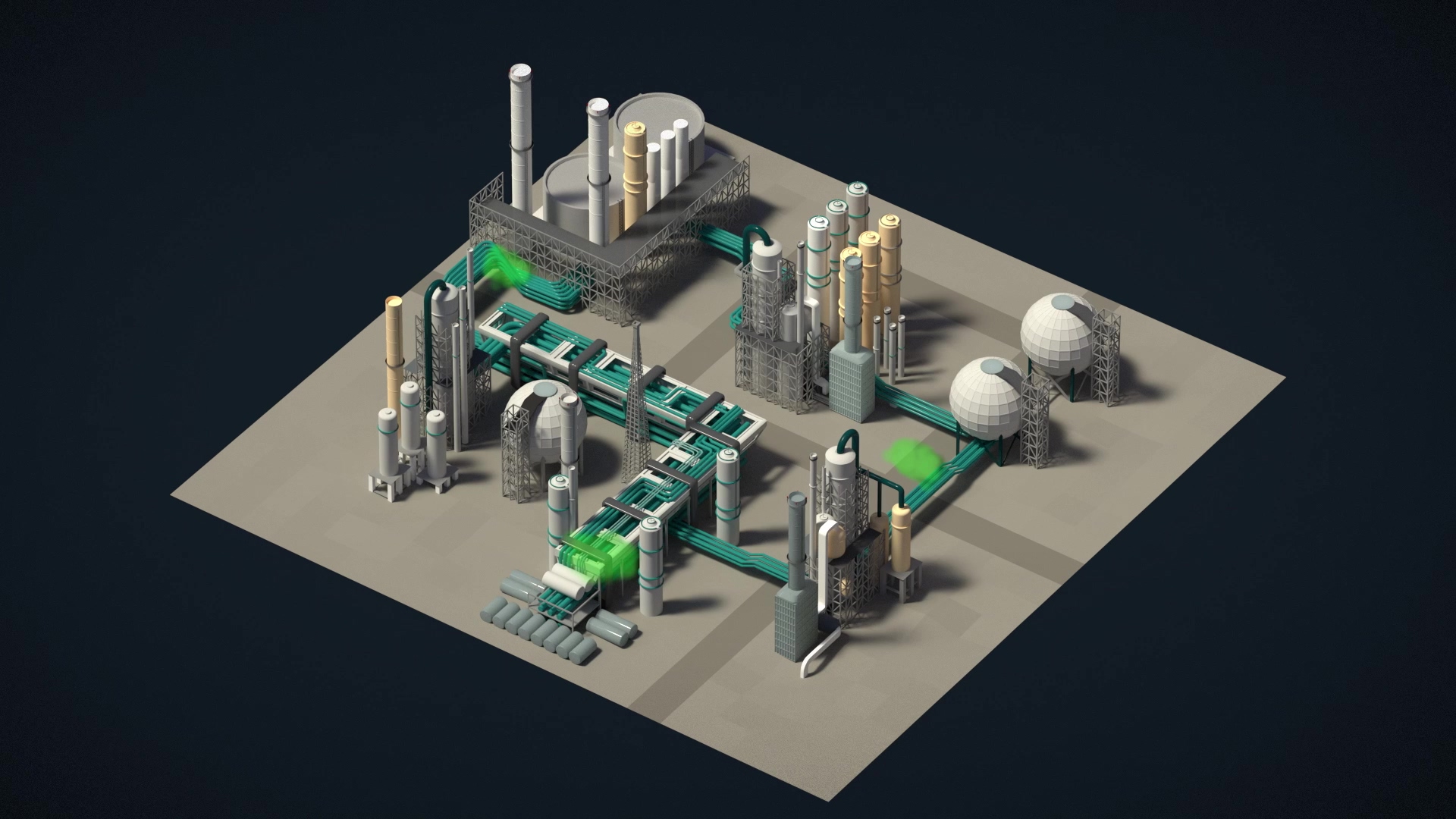

Transform your emissions management with mRegz™ AirCompliance—engineered for precision, scalability, and seamless integration across your processes.

Key Benefits

ONE Solution, Multiple Applications

-2.png)

Automated Alerts

Early Detection

Visual Tools

Scalability

Achieve Measurable Results in Just 1-3 Months

Unlock the power of mRegz™ AirCompliance to transform your operations quickly and effectively.

Experience improvements that matter:

Enhanced Safety

Protect personnel with advanced emissions detection systems.

Community Trust

Minimize environmental impact and foster trust with neighboring communities.

Cost Savings

Reduce expenses tied to inspections, scaffolding, and manual exception handling.

Operational Efficiency

Streamline workflows with smarter, more effective compliance strategies.

Transform emissions management into smarter, safer, and more sustainable operations—faster than you thought possible.