mCluez™ Corrosion Monitoring

Enhance safety, compliance and operational efficiency from corrosion for process industries

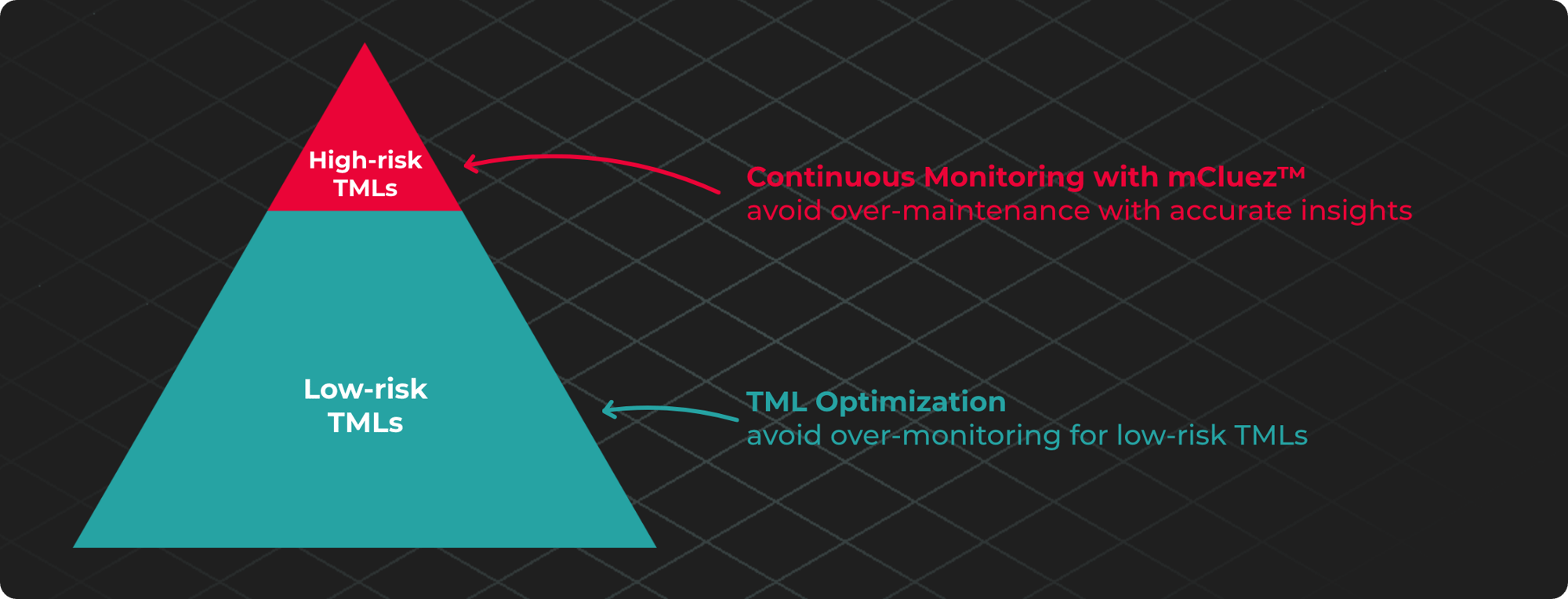

Avoid over-monitoring and over-maintenance of fixed assets from unexpected corrosion, catastrophic events and unplanned maintenance

Embark on a journey of innovation with the mCluez™, meticulously designed for corrosion monitoring. Harnessing cutting-edge ultrasonic sensor technology, advanced analytics, and dashboards, mCluez™ corrosion monitoring solution empowers corrosion engineers and chief inspectors to proactively prevent corrosion, ensuring the safe and efficient operation of industrial assets. Our state-of-the-art non-intrusive transducer-based solution employs a comprehensive Non-Destructive Testing (NDT) technique to detect flaws and imperfections in materials ensuring structural integrity. Fueled by the AIoT (Artificial Intelligence of Things) approach and NDE4.0 (Non-Destructive Evaluation) methods, this solution equips plant operators to strategically plan maintenance or repair activities for optimized asset performance.

Monitor what matters & only maintain when it matters!

Case Study

Discover how mCluezTM helped a large U.S. refinery identify increased corrosion rates outside the scheduled maintenance window with appropriate resolution taken in less than 3 months.

Customer Success Stories

- Asset: Alkylation process unit

- Problem: High corrosion on a critical vessel affects equipment life and performance with current manual inspections.

- Solution: mCluez™ solution highlighted high corrosion rates, aiding in process troubleshooting for insights on equipment life and safety impact.

- Benefit: Early identification of high corrosion rates informed timely plant decisions, assessing their impact on equipment life.

- Asset: Deisohexanizer (DIH) process unit

- Problem: Detecting high corrosion through manual thickness readings can take years, making it inefficient and time-consuming to assess its impact on equipment life.

- Solution: mCluez™ solution revealed an unexplained spike in corrosion rates, aligning with process troubleshooting that identified a timeline when a corrosion inhibitor pump was inactive.

- Benefit: Early identification of corrosion rate changes provided timely insights, preventing unplanned downtime and safeguarding fixed asset health.

- Asset: Degassing system

- Problem: Low temperatures elevate corrosion rates within the degassing system.

- Solution: The timely insights from the mCluez™ solution enabled the fixed equipment and operations teams to effectively adjust temperatures, mitigating elevated corrosion rates.

- Benefit: Proactive corrosion detection preempted process disruptions and unplanned downtime.

- Asset: Alkylation process unit

- Problem: High corrosion on a critical vessel affects equipment life and performance with current manual inspections.

- Solution: mCluez™ solution highlighted high corrosion rates, aiding in process troubleshooting for insights on equipment life and safety impact.

- Benefit: Early identification of high corrosion rates informed timely plant decisions, assessing their impact on equipment life.