Operational Predictability for Industrial Monitoring: Why Your Plant Needs the Equivalent of a Smartwatch

In today’s industrial landscape—spanning petrochemical plants, refineries, and chemical facilities—operational predictability has emerged as a vital capability. It is the difference between managing unexpected downtime or safety incidents and running a smooth, compliant, and cost-efficient operation. While the term may sound technical, the concept becomes clearer when you compare it to something familiar: how we monitor our own health.

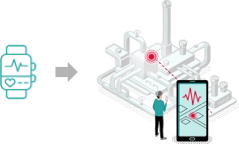

From Annual Check-Ups to a Plant Smartwatch

Recall how, in the past, health monitoring was limited to periodic doctor visits—a snapshot in time that might miss early symptoms. Today, millions wear smartwatches that continuously track heart rate, sleep, and oxygen levels, sending alerts before problems become serious.

Similarly, industrial plants have traditionally relied on scheduled, manual inspections of emissions and corrosion—akin to yearly check-ups. But now, with solutions like mPACT2WO, plants have their own “smartwatch” that continuously monitors emissions and corrosion, providing early anomaly detection and contextual alerts in real-time. This shift is transforming how industrial sites maintain safety, regulatory compliance, and asset integrity.

What Is Operational Predictability?

Operational predictability means having the plant’s monitoring systems anticipate and identify anomalies early—whether it’s emissions leaks or corrosion—before they escalate into costly failures or regulatory exceptions.

It enables teams to:

- Detect leaks or abnormal emission events quickly.

- Monitor corrosion trends with precision, corrected for temperature and material velocity.

- Receive actionable alerts enriched with operational context to prioritize responses.

- Transition from manual, periodic rounds to automated, event-driven inspections.

Together, these capabilities allow operators to act decisively and efficiently, reducing risk and downtime.

The Paradigm Shift Enabled by mPACT2WO

At the heart of this transformation is the mPACT2WO platform, a comprehensive solution that integrates advanced sensors, software analytics, and operational workflows.

- mRegz™ AirCompliance delivers early emissions detection with operational context, helping reduce inspection effort and prevent compliance breaches.

- mCluez™ Corrosion Monitoring uses high-fidelity ultrasonic sensors combined with dynamic corrections for temperature and material velocity to provide reliable corrosion thickness data and trends.

- Automated anomaly alerts transition field teams from scheduled notepad rounds to informed, real-time interventions.

Real Impact: Proven Use Cases

This isn’t theory—it’s already making a difference across multiple industrial sites:

- Early leak detection has averted catastrophic shutdowns caused by high-pressure failures.

- Abnormal emissions in tank vents were caught early, avoiding regulatory penalties and environmental harm.

- Corrosion monitoring has kept critical units like alkylation plants online, preventing costly outages.

- Remote and hard-to-reach sites now benefit from continuous monitoring, cutting inspection costs and reducing cleanup after exceptions.

These outcomes underscore how operational predictability safeguards people, assets, and the environment.

Why Predictability Drives Business Value

Beyond operational safety and regulatory compliance, predictability delivers significant business advantages:

- Reduced downtime and maintenance costs through early intervention.

- Enhanced production margins by minimizing disruptions.

- Extended asset life via proactive corrosion management.

- Sustainability gains by limiting emissions and waste.

- Accelerated growth supported by technology-enabled services and outcome-based solutions.

In Closing: Predictability Is Power

Just as your smartwatch quietly watches over your health every second, the mPACT2WO platform diligently monitors your plant—helping you detect and fix emissions and corrosion issues before they become emergencies. This paradigm shift from manual inspections to automated, intelligent anomaly detection is redefining industrial monitoring for safer, smarter, and more sustainable operations.